-

p.p1 {margin: 0.0px 0.0px 0.0px 0.0px; text-align: justify; font: 10.5px Helvetica} Completely annealed steel or blanks heated to Ac3 above 20-30 ℃, heat for a certain period of time, so that the steel organization is completely austenitized after the furnace slowly cooled to below 500 – 60...Read more »

-

p.p1 {margin: 0.0px 0.0px 0.0px 0.0px; text-align: justify; font: 10.5px Helvetica} Annealing is to heat the steel to a certain temperature and heat for a certain period of time, and then cooled at a slow rate to obtain a heat treatment process close to the equilibrium state. The annealing is div...Read more »

-

Alloy 625 is Nickel-Chromium-Molybdenum-Columbium alloy,which possess excellent resistance to oxidation and corrosion over a broad range of corrosive environment.It has outstanding strength and toughness at temperatures ranging from cryogenic to elevated temperatures in the range of 2000 degrees ...Read more »

-

Inconel Alloy 625 also called UNS designation N06625 is a nickel-based special alloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and...Read more »

-

In metallurgy,stainless steel is inox steel with a minimum of 10.5% chromium contents by mass.It have corrosion resistance and is wisely used by many applications. There are various grade and surfaces finishes of stainless steel to suit the environment the alloy must endure. Stainless steel diffe...Read more »

-

Vacuum arc remelting (VAR) is a secondary melting process for production of metal ingots with elevated chemical and mechanical homogeneity for highly demanding applications.The VAR process has revolutionized the specialty traditional metallurgical techniques industry, and has made possible incred...Read more »

-

The electroslag remelting (ESR) process is used to remelt and refine steels and various super-alloys, special alloy, resulting in high-quality ingots. This process can be started up through vacuum induction melting. The ESR process uses the as-cast alloy as a consumable electrode. Electric c...Read more »

-

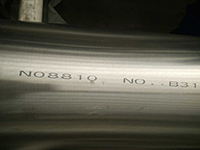

Alloy UNS N08800 is normally employed in service temperatures up to and including 1100 degrees Fahrenheit (539 degrees celsius). Alloy UNS N08810,UNS N8811,and UNS N08120 are normally employed in service temperatures above 1100 degrees fahrenheit(539 degrees celsius) where resistance to creep and...Read more »

-

In the process of steel making, the liquid steel which is produced from low cost material must be refined, and it require that making the efficient continuous casting into continuous casting slabs with high-temperature processing property. Ex-federal Germany developed the Vacuum Oxygen Decarburiz...Read more »

-

Actually in all of the chemical compositions, the most impact of contribution for corrosion resistance is not Ni, but Cr, which make sure the ferric stainless steel. It usually contains 11% ~50%. But if the Cr is over 50% that will broke the heat and cold processing properties...Read more »

-

p.p1 {margin: 0.0px 0.0px 0.0px 0.0px; font: 14.0px Times; color: #101010; -webkit-text-stroke: #101010} span.s1 {font-kerning: none} The flow stress behaviors and microstructure characteristics of C-276 alloy were investigated by isothermal compression tests in the temperature range of 1100-1250...Read more »

-

Now steel is sustainable development material at present and in the future as its a variety of properties. Steel’s generality and adaptability embody itself various properties. (1)be suitable to cold-work and hot-work. (2) possess weldable; (3) be provided with hardness, ductility, abradability. ...Read more »

-

No doubtfully, we are profesionally supplying nickel base alloy,super duplex,austenitic,ferritic stainless steel seamless & weld pipe and tube. also supply semi-finish products: non-ferrous bar,plate,sheet,cut to length. Now we add our valuable service: Processing service for fitting,flange,...Read more »

-

pplications: Boiler, heater , heat exchanger, condenser, instrumentation ,pipe lines. Available Specifications: ASTM/ASME B/SB163 for nickel alloy condenser and heat exchanger tubes. ASTM/ASME B/SB165 for nickel copper alloy tube and pipe ASTM/ASME B/SB167 for Ni-Cr-Iron Alloys (UNS N06601 , UN...Read more »

-

Standard material Nickel Chromium Iron Manganese max Aluminum Carbon Copper Silicon Sulfur max Titanium Molybdenum Phosphorus max Cerium 铈 Zirconium 锆 Yttrium 钇 Tungsten 钨 Cb+Ta Cobalt Boron硼 Nitrogen material Ni Cr Iron Mn Al C Cu Si S Ti Mo P Ce Zr Y W Cb+...Read more »

-

Standard material Tensile Strength,Min PSI (MPa) Yield Strength (0.2% offset) Min(Mpa) Elongation in 2 in. or 50mm or 4D,Min.,% SB-163 Nickel N02200 55000 (379) 15000 (103) 40 65000(448) SR 40000 (276) SR 15 SR SB-163 Low C Nickel N02201 50000 (345) 12000 (83) 40 60000 (...Read more »

-

(Super) Duplex (Ferritic / Austenitic ) Steel Seamless Pipe and Tube A790/A790M: Standard Specification for Seamless And Welded Ferritic / Austenitic Stainless Steel Pipe. A789/A789M: Standard Specification for Seamless and Welded Ferritic/ Austenitic Stainle...Read more »

-

REF.STANDARD EN 10216-5/ASTM A312 GRADE Rp0.2 Rp1.0 Rm El% 1.4404/TP316L 190 225 490-690 40 1.4541/TP321 OD≤9.5 205 235 515-730 35 OD≥9.5 200 235 500-730 35 1.4571/TP316Ti 210 245 515-730 35 1.4301/TP304/TP304L 205 230 515-700 40 1.4301/1.4306/TP304/TP304L...Read more »

- English

- Français

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Me..

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ay..

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbai..