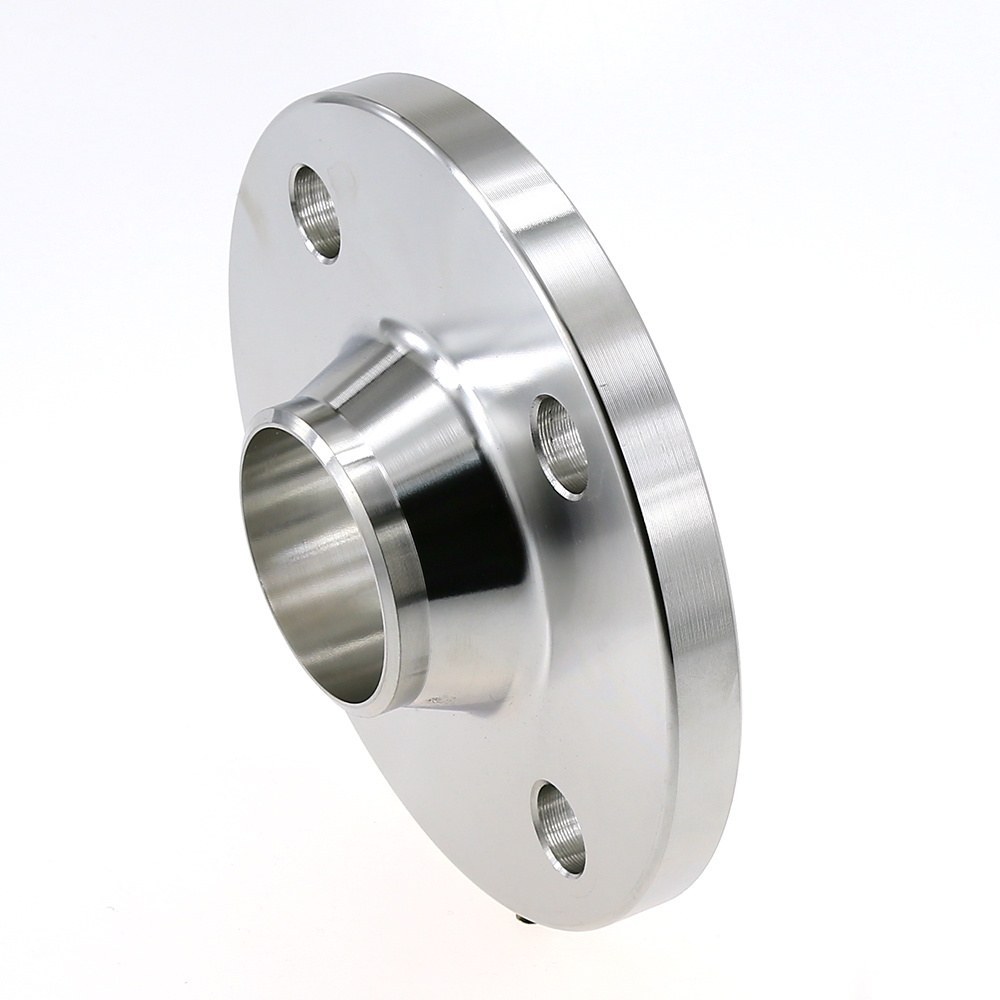

weld neck flange

Product Detail

Product Tags

| ISO7005-1:1992(E) | EN1092:2007(E) | BS4504:3.1 – 1989 | ||||||

| WN flange type11 | WN flange type11 | WN flange Code111 | ||||||

| PN2.5 | DN10-DN4000 | PN2.5 | DN10-DN4000 | PN2.5 | DN10-DN4000 | |||

| PN6 | DN10-DN3600 | PN6 | DN10-DN3600 | PN6 | DN10-DN3600 | |||

| PN10 | DN10-DN3000 | PN10 | DN10-DN3000 | PN10 | DN10-DN3000 | |||

| PN16 | DN10-DN2000 | PN16 | DN10-DN2000 | PN16 | DN10-DN2000 | |||

| PN20 | DN15-DN1500 | PN25 | DN10-DN2000 | PN25 | DN10-DN2000 | |||

| PN25 | DN10-DN2000 | PN40 | DN10-DN1600 | PN40 | DN10-DN60 | |||

| PN40 | DN10-DN600 | PN63 | DN10-DN1200 | |||||

| PN50 | DN15-DN1500 | PN100 | DN10-DN500 | BS3293:1960 | ||||

| PN110 | DN15-DN1500 | PN160 | DN10-DN300 | Class 150 | 26″-48″ | |||

| PN150 | DN15-DN1200 | PN250 | DN10-DN300 | Class 300 | 26″-36″ | |||

| PN260 | DN15-DN600 | PN320 | DN10-DN250 | Class 400 | 26″-36″ | |||

| PN420 | DN15-DN300 | PN400 | DN10-DN200 | Class 600 | 26″-36″ | |||

| JIS B2220:2004 | ASME B16.5-2003 | ASME B16.47-2006 | ||||||

| 5K | DN10-DN1500 | 1/2″-24″ | CLASS 150-2500 | 26″-60″ | CLASS 150-900 | Series A | ||

| 10K | DN10-DN1500 | 26″-60″ | CLASS 75-900 | Series B | ||||

| 16K | DN10-DN600 | API605-1988 | ||||||

| 20K | DN10-DN600 | 26″-60″ | CLASS 75-900 | TYPE C | ||||

| 30K | DN15-DN400 | DIN2631-11 | PN 6 | DN10-DN3600 | ||||

| DIN2632-11 | PN 10 | DN10-DN3000 | ||||||

| MSS SP44-1996 | DIN2633-11 | PN 16 | DN10-DN2000 | |||||

| 12″-60″ | CLASS 150-600 | DIN2634-11 | PN 25 | DN10-DN1000 | ||||

| 12″-48″ | CLASS 900 | DIN2635-11 | PN 40 | DN10-DN600 | ||||

| DIN2636-11 | PN 63 | DN10-DN400 | ||||||

| DIN2637-11 | PN10 | DN10-DN350 | ||||||

Forged Flanges

Flange Types: Slip-on flange, threaded flange,weld neck flangeblind flange, socket weld flange, lap joint flange, orifice flange,blind flange,spaddle flange,loose flange,plate flange.

Flange Face Configurations:

All Flanges are available in raised face ,flat face configurations.

Weld Neck Bore Flanges:

Available in all bore sizes

Wall Pressure Ratings:

150#, 300#, 600#, 900#, 1500#, 2500#

Specialty Flanges:

Larger than 36″ flanges regularly available. Hard-to-find configurations and wall ratings are our specialty.

ASME B16.5, annealed and fully machined, raised face, smooth finish (125-250 RMS / 3.2-6.3µM) to MSS-SP6, hardness to NACE MR0175 latest edition. IC checked to ASTM A262 E and PMI tested.